◆主要性能规范

|

材质名称 |

适用温度 |

适用介质 |

|

ASTMA216WCB |

≤4250℃ |

油品、蒸气、水 |

|

WCB |

|

CF8 |

≤200℃ |

硝酸类 |

|

0Cr18Ni9 |

|

CF8M |

≤200℃ |

硝酸类 |

|

00CrNi12M02Ti |

|

CF3 |

≤2000℃ |

硝酸类 |

|

00Cr18Nil0 |

|

CF3M |

≤200℃ |

硝酸类 |

|

00Cr17Ni14M02 |

◆主要试验压力 (API 598)

|

公称压力 PN(MPa) |

150 |

300 |

600 |

Lb |

|

壳体试验压力 |

3 |

7.8 |

15.4 |

MPa |

|

高压密封试验压力 |

2.2 |

5.6 |

11.2 |

|

低压气密封试验压力 |

0.5~0.7 |

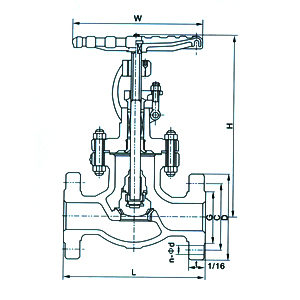

◆ 150Lb外形尺寸和连接尺寸

|

规格 |

L |

D |

t |

G |

C |

n-φd |

W |

≈ H |

|

1/2″ |

mm |

108 |

89 |

10 |

35 |

60.5 |

4-15 |

125 |

241 |

|

in |

4.25 |

3.5 |

0.47 |

1.38 |

2.38 |

4.059 |

4.92 |

6.65 |

|

3/4″ |

mm |

117 |

98 |

11 |

43 |

70 |

4.15 |

125 |

241 |

|

in |

4.61 |

3.86 |

0.47 |

1.69 |

2.76 |

4-0.59 |

4.92 |

7.08 |

|

1″ |

mm |

127 |

108 |

12 |

51 |

79.5 |

4.15 |

125 |

242 |

|

in |

5 |

4.25 |

0.47 |

2 |

3.13 |

4-0.59 |

4.92 |

7.48 |

|

11/2″ |

mm |

165 |

127 |

15 |

73 |

98.5 |

4.15 |

180 |

286 |

|

in |

6.5 |

5 |

0.56 |

2.87 |

3.88 |

4-0.62 |

7.09 |

13.66 |

|

2″ |

mm |

203 |

152 |

16 |

92 |

120.5 |

4-19 |

180 |

368 |

|

in |

8.00 |

6.00 |

0.625 |

3 62 |

4.75 |

4-0.75 |

7.09 |

14 |

|

21/2″ |

mm |

216 |

178 |

18 |

105 |

139.5 |

4.19 |

240 |

387 |

|

in |

8.5 |

7 |

0.69 |

4.12 |

5.50 |

4-0.75 |

9.45 |

15.00 |

|

3″ |

mm |

241 |

190 |

19 |

127 |

152.4 |

4-19 |

280 |

411 |

|

in |

9 5 |

7.50 |

0.75 |

5 |

6 |

4-0 75 |

11.02 |

16.25 |

|

4″ |

mm |

292 |

229 |

24 |

157 |

190.5 |

8.19 |

280 |

454 |

|

in |

11.50 |

9.00 |

0.94 |

6.19 |

7 5 |

8-0.75 |

11.02 |

19.68 |

|

6″ |

mm |

406 |

279 |

26 |

216 |

241.5 |

8-22 |

360 |

541 |

|

in |

16 |

11.00 |

1.00 |

8.5 |

9.50 |

8-0.88 |

14.17 |

22.25 |

|

8″ |

mm |

495 |

343 |

29 |

270 |

298 5 |

8-22 |

450 |

651 |

|

in |

19.5 |

13.5 |

1.12 |

10.62 |

11.75 |

8-0.88 |

17.75 |

26.00 |

1.法兰连接尺寸按ANSI B16.5

2.阀门结构长度尺寸按ANSl B16.10

[1] [2] 下一页 |